Product Description

Industrial Nitrocellulose

Superior Clarity: Solutions made with our nitrocellulose are exceptionally clear, dramatically improving the quality of the final product.

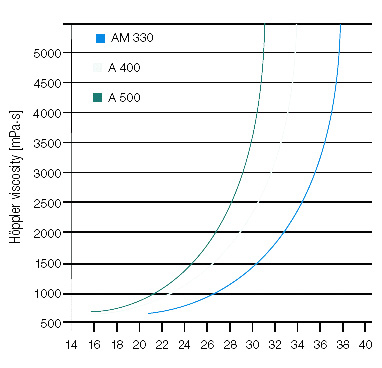

Choice of viscosities: Our nitrocellulose is produced in a range of viscosity to give formulators complete freedom to develop the properties they want.

Guaranteed consistency & quality: We use stringent quality control and batch production methods to help us meet increasingly high performance and quality standards demanded by modern industry and consumers.

Convenient packaging & storage options: Our nitrocellulose is available in a range of packs from versatile 10 kg fibreboard cartons for manual handling to 136 kg fibreboard drums.

On-going research & development: Our team of dedicated professionals has the skills, commercial expertise and breadth of vision to evolve state – of the art products and services.

Safer to handle: Our nitrocellulose is more sensitive to impact and friction than flake nitrocellulose.

GRADES

| Specifications | Viscosity (sec) | Acidity (%) |

| RS 1/16 sec | 1.0 ~ 1.6 | Below 0.05 % |

| RS 1/8 sec | 1.6 ~ 2.9 | Below 0.04 % |

| RS 1/4 sec | 3.0 ~ 5.9 | Below 0.04 % |

| RS 1/2 sec | 3.0 ~ 5.0 | Below 0.03 % |

| RS 1 sec | 5.1 ~ 9.0 | Below 0.03 % |

| RS 5 ~ 6 sec | 4.5 ~ 6.5 | Below 0.03 % |

| RS 10 ~ 15 sec | 10 ~ 15 | Below 0.03% |

| RS 15 ~ 20 sec | 15 ~ 20 | Below 0.03% |

| RS 30 ~ 40 sec | 30 ~ 40 | Below 0.03% |

| RS 60 ~ 80 sec | 60 ~ 80 | Below 0.03% |

| RS 120 sec | 110 ~ 140 | Below 0.03% |

| RS 150 sec | 140 ~ 170 | Below 0.03% |

NITROGEN CONTENT & VISCOSITY

Nitrogen Content:Industrial nitrocellulose produced has a nitrogen content between 10.7% and 12.2% with products specially manufactured within three ranges. The nitrogen content of the nitrocellulose affects the polymer solubility and its thermoplasticity. |

|

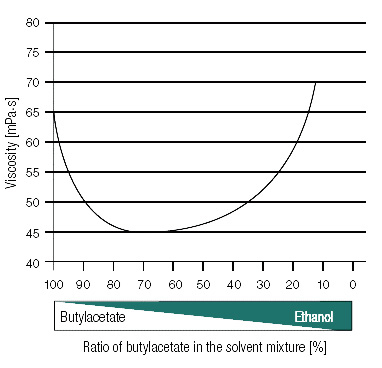

Viscosity:As with all polymers, the strength and durability of the nitrocellulose lacquer film depends on the polymer molecular weight, which in turn is related to the product’s viscosity. |

|

TRANSPORTATION

- The product shall be stored and shipped according to state regulations of storing and shipping for dangerous goods.

- The package shall be handled with care and avoided to impact with iron articles.

- Do not open it in open air or under direct sunlight.

- It is not allowed to transport the product by truck without canvas cover.

- The product should not be transported and stored together with acid, alkali, oxidant, reductant, inflammables, explosive and igniter.

- N.C. shall be stored in order in the special storehouse that must be cool, ventilated, fire-prevented and no tinder near its surroundings.

STORAGE

- Either damped N.C. or plasticised N.C.COTTON-chip should be stored in a dark, cool and ventilated place far away from any heat producers.

- In the sites for storing or treating N.C, open fire or other ignition sources should be forbidden and an eyecatching sign of “Smoking and lighting fire strictly forbidden” should be hung in a proper place.

- It should be strictly prohibited to open the packages containing N.C. in the storehouse for sampling.

- The N.C. for use should be taken out of the storehouse according to the principle of FIFO (first-in, first-out) and it had better be used up within one year from the packing date.

- Anti-explosion light & devices should be used in the storage of N.C. and the mechanical apparatus and tools liable to produce spark are not allowed to use.

PACKAGING (As per 40′ Container)

| S.No. | Weight | Boxes | Fibre Drums | Metal Drums |

| 1. | 10 kg | 1900 | – | – |

| 2. | 20 kg | 900 | – | – |

| 3. | 28 kg | 680 | – | – |

| 4. | 30 kg | – | 520 | – |

| 5. | 32 kg | – | 520 | – |

| 6. | 35 kg | – | 520 | – |

| 7. | 37 kg | – | 520 | – |

| 8. | 40 kg | – | 520 | – |

| 9. | 45 kg | – | 520 | – |

| 10. | 70 kg | – | 160 | – |

| 11. | 80 kg | – | 160 | – |

| 12. | 90 kg | – | 160 | – |

| 13. | 100 kg | – | 160 | 144 |

| 14. | 110 kg | – | 160 | 144 |

| 15. | 120 kg | – | 160 | 144 |

| 16. | 136 kg | – | 160 | – |

COMPARISON CHART

| Holaso | Nobel | Bergerac | Dow wolff | Nitrex |

| RS 1/16 sec | DHX 3/5 | E19 | E330 | HX 3/5 |

| RS 1/8 sec | DHX 5/10 | E24 | – | HX 5/8 |

| RS 1/4 sec | DHX 8/13 | E27 | – | HX 20/30 |

| RS 1/2 sec | DHX 30/50 | E35 | E620 | HX 30/50 |

| RS 1 sec | – | E40 | – | HX 70/90 |

| RS 5 ~ 6 sec | DHL 25/45 | E70 | E840 | HL 25/45 |

| RS 10 ~ 15 sec | DHL 120/170 | E80 | E840 | – |

| RS 15 ~ 20 sec | – | E90 | E950 | HL 120/170 |

| RS 30 ~ 40 sec | DHM 10/25 | E110 | E1160 | HM 10/25 |

| RS 60 ~ 80 sec | – | – | – | HM 40/60 |

| RS 120 sec | – | E140 | E1250 | – |

| RS 150 sec | – | E150 | – | – |